We live the honest production of bandsaw blades, which we are constantly developing

and thus we strive to the perfect woodworking tool.

Aldought we strive to deliver the highest quality products to our customers, technologies on the market have become less suitable over time. Therefore, we set about improving our production machinery and processes.

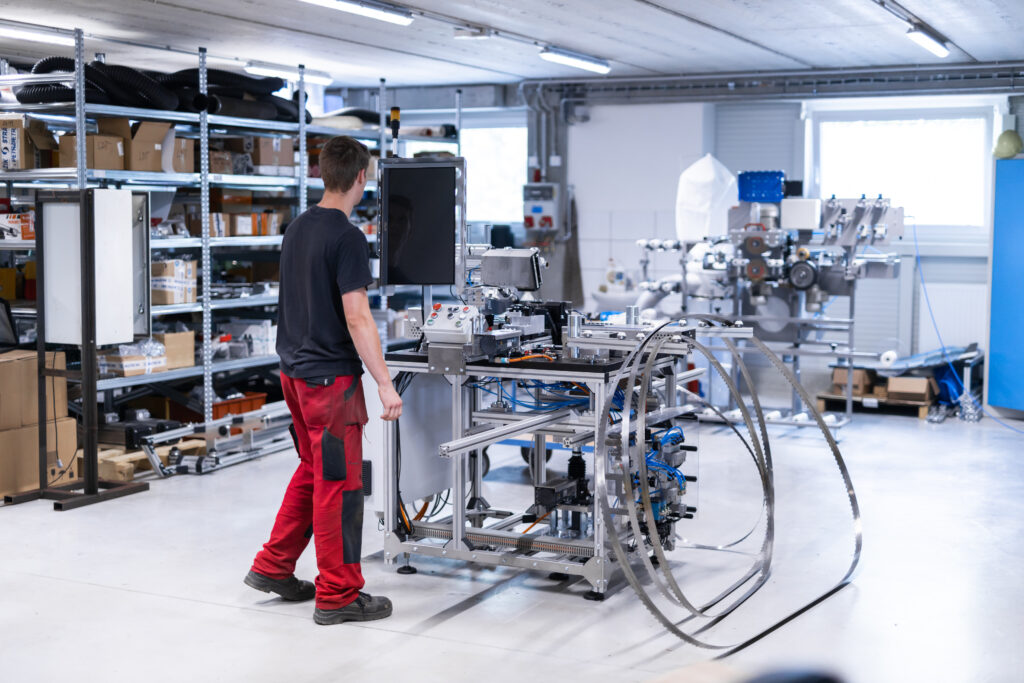

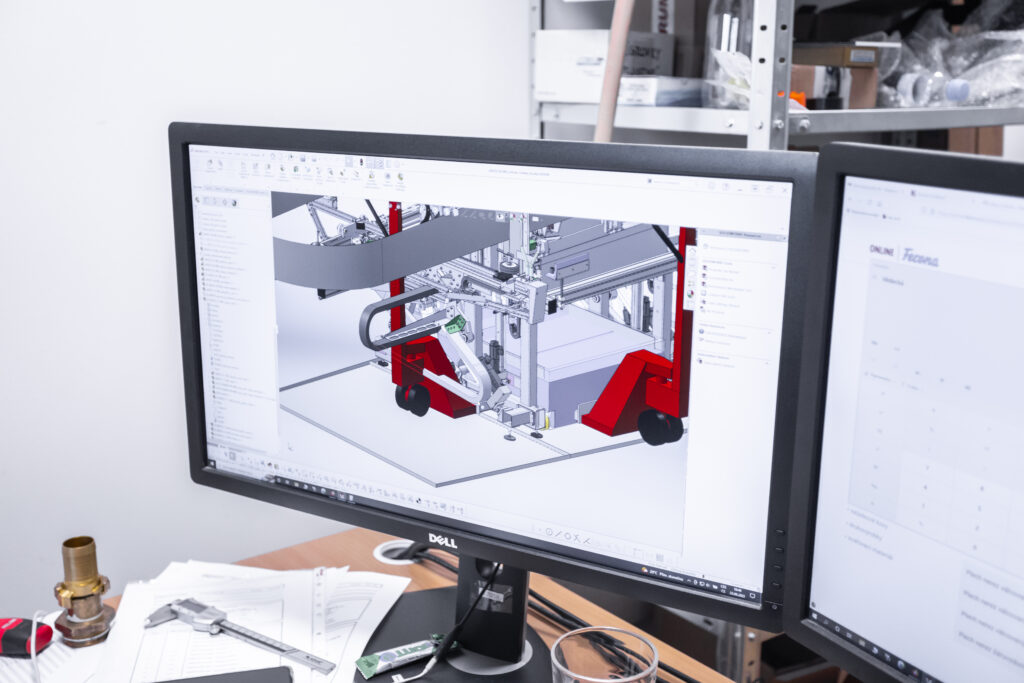

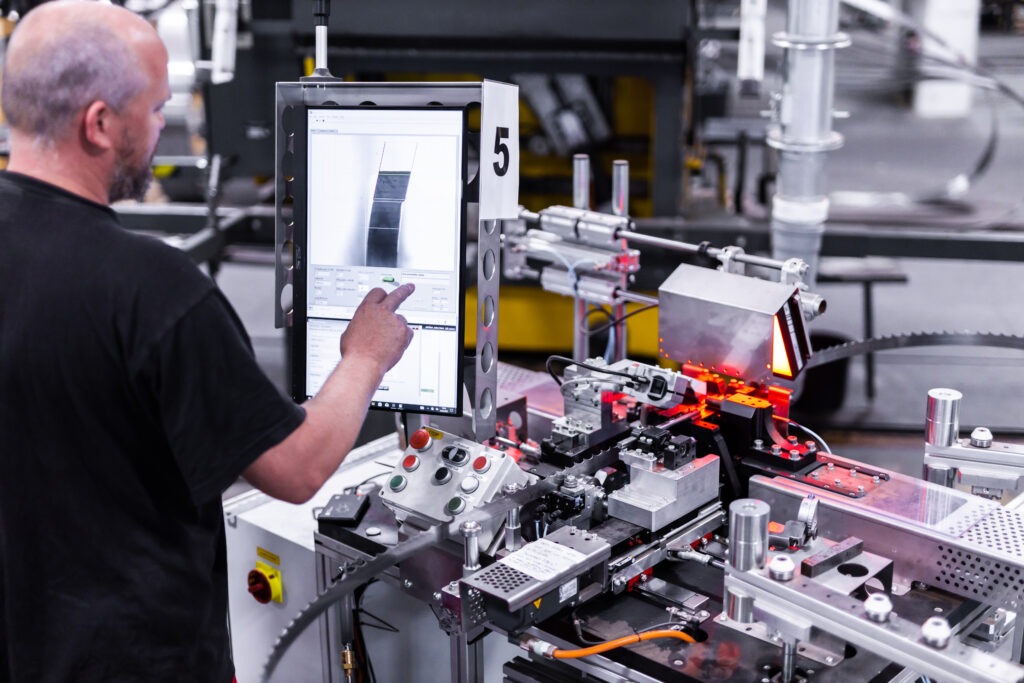

This has led us to develop our own machines to meet the highest requirements that are a necessity in every modern company today (remote machine control, information retrieval from the company system, camera measurement, automatic machine adjustment, etc.).

Our developers work to develop machines and systems that they then see their colleagues using in the field and observing their daily shortcomings and advantages. This enables them to react to production requirements and gradually fine-tune everything to perfection.

Each new creation from our production then naturally carries the knowledge of the previous models, so that everything is more sophisticated in terms of user and technology.

The expansion of production in the newly completed extension of the production hall will also enable us to build a centre for our own development activities in the market of machine design, which should contribute to ensuring a higher proportion of robotics in our company in the future.

The aim of developing our own machines is to make the work of our colleagues as easy as possible and to bring the most sophisticated tools available on the world market.

The reward for our efforts in the field of innovation and development is not only

TOMÁŠ DUDR

their reliable sharp operation leading to optimized production,

but also the success of our projects in professional competitions!

Dudr Tools s.r.o. is a successful applicant for support within EU co-financed grant programs:

Support Program: OP PIK – Application – Call IV

Project Registration Number: CZ.01.1.02/0.0/0.0/17_106/0012263

Project Title: Automatic rolling bench for band saws at Dudr Tools s.r.o.

Project Objective: Development of an automatic rolling machine intended for the production of band saws for the woodworking industry and its certification.

Co-financing:

Support Program: OP PIK – Application – Call VII

Project Registration Number: CZ.01.1.02/0.0/0.0/19_262/0019167

Project Title: Automatic stellite-tipping machine and grinder for band saws at Dudr Tools s.r.o.

Project Registration Number: CZ.01.1.02/0.0/0.0/19_262/0019183

Project Title: Automatic setting machine and grinder for narrow band saws at Dudr Tools s.r.o.

Project Objective: Development and production of machines for the manufacture and servicing of band saws, enabling progress in automation, user comfort, and solution complexity to a qualitatively and technically new level.

Co-financing:

Support Program: OP PIK – Application – Call IX

Project Registration Number: CZ.01.1.02/0.0/0.0/21_374/0026698

Project Title: Tooth-cutting laser for band saws

Project Objective: Development of a prototype to be deployed in in-house production. This will achieve greater automation and optimization of the production process.

Co-financing:

Support Program: OP PIK – Potential – Call VIII

Project Registration Number: CZ.01.1.02/0.0/0.0/21_375/0027028

Project Title: Dudr Development Centre

Project Objective: Creation of optimal conditions for the R&D department engaged in the development of machines for the production and servicing of band saws for the woodworking industry.

Co-financing:

Support Program: NPO (National Recovery Plan) – Digital Enterprise – Call I

Project Registration Number: CZ.31.2.0/0.0/0.0/22_014/0003289

Project Title: Digitalization of Dudr Tools s.r.o.

Project Objective: To increase the level of digitalization of the company through the acquisition of hardware and software. A new ERP and PLM system will be implemented, backup and cybersecurity will be strengthened. By optimizing business processes, production can be further developed and maximum efficiency achieved.

Co-financing:

Support Program: NPO (National Recovery Plan) – Creative Voucher

Project Registration Number: 0380001122

Project Title: Creative Voucher Dudr Tools s.r.o.

Project Objective: Establishing cooperation with an experienced creative professional who will help our company express its mindset and corporate philosophy through external presentation. Emphasis is placed on presentation towards all our business partners who come into direct personal contact with our company, so that it reflects the company’s philosophy and its motto “I feel good here.”

Co-financing:

Support Program: OP TAK – Marketing – Call I

Project Registration Number: CZ.01.02.01/04/23_017/0001675

Project Title: Dudr Tools: Marketing

Project Objective: To increase sales of core band saws and circular saws for the woodworking industry manufactured by Dudr Tools s.r.o.

Co-financing:

Support Program: OP TAK – Marketing – Call II

Project Registration Number: CZ.01.02.01/04/24_044/0005526

Project Title: Dudr Tools: Presentation at international trade fairs

Project Objective: To increase sales of core band saws and circular saws for the woodworking industry manufactured by Dudr Tools s.r.o.

Co-financing:

Support Program: Employment Plus – Call 03_23_047

Project Registration Number: CZ.03.01.03/00/23_047/0003623

Project Title: Dudr Tools: Corporate Training

Project Objective: To increase the competence level of employees through professional training that meets the current needs of the employer and the demands of the changing labour market.

Co-financing:

Support Program: NPO (National Recovery Plan) – Creative Vouchers II – Call No. 0461/2024

Project Registration Number: 0461000070

Project Title: Creative Voucher II Dudr Tools s.r.o.

Project Objective: Mutual cooperation of creative professionals from the National Creative Gallery and the business sector in the field of creative innovations with the aim of creating designs for company printed materials and company vehicle branding, all with a unified and widely understandable design.

Co-financing:

Dudr Tools is the implementer of the project National Competence Centre for Mechanical Engineering

Project Number: TN02000018

Project Implementation Period: 1 January 2023 – 31 December 2028

Annotation: The National Competence Centre for Mechanical Engineering (NCKS) focuses on research, development, and innovation activities necessary to increase the competitiveness of the Czech engineering industry in the field of medium and light mechanical engineering. NCKS addresses key topics relevant for future innovations of machines and equipment. The strategic research agenda reflects customer and user requirements, as well as economic, environmental, social, and especially technological demands. Emphasis is placed on increasing machine and equipment performance and efficiency, reducing their energy intensity, automating production processes, saving materials and reducing environmental impacts, digitalizing processes, and taking into account trends within Industry 4.0. The National Competence Centre for Mechanical Engineering project is co-financed with state support from the Technology Agency of the Czech Republic under the National Competence Centre Program. This project is funded under the National Recovery Plan from the European Recovery and Resilience Facility.

Co-financing: