Summer holidays

We would like to inform you that our company will be closed from 3.7.2023 till 7.7.2023 because of summer holidays. During this period our production and services will be limited.

On the 27th calendar week we will not accept any orders, so we ask that you secure bandsaw blades and circular saws in advance.

We look forward to seeing you again in the 28th calendar week.

After a year, Lanáček again

Our most popular Dudr family day event in Lanáček was successful again. In the beginning the weather greeted us with a garden shower, but with the start of the event, the sun came out as expected. The amount of adults and children numbered almost 200 guests. The spaces of the area were filled with heads wearing red Dudr hats. The great magician Tomasiano first entertained the children, and then with his micro magic and card tricks, he gradually amazed the numerous groups of spectators. The daredevils enjoyed the adrenaline attractions. Our stomachs experienced euphoria in the form of tasty catering and roast pork. Everything went perfectly. We look forward to seeing you again next year!

Dudr Tools at Ligna 2023

We participated at the Ligna fair for many time, yet this year was our debut. For the first time ever, we presented ourselves here by a separate stand with a respectable area of 64 m2. We wanted to reflect the company’s progress, trend and functionality at the design of the stand. Everything was excellently designed by an experienced industrial designer, Martin Kožucharov, and he guaranteed that our stand attracted the attention of visitors and gained positive feedback. Truhlářství Světlík took care of the precise production of wooden components, and Board Vision ensured trouble-free assembly and dismantling. In addition, the enthusiasm of our salers, who actively communicated with everyone who visited us, and we cannot evaluate the Ligna fair in any other way than successfully and beneficially. We are looking forward to all the new business opportunities that Ligna has revealed to us. In two years, we will stand on the gate again and show ourselves to be a bit more advanced, because Dudr Tools will definitely not step on the same place.

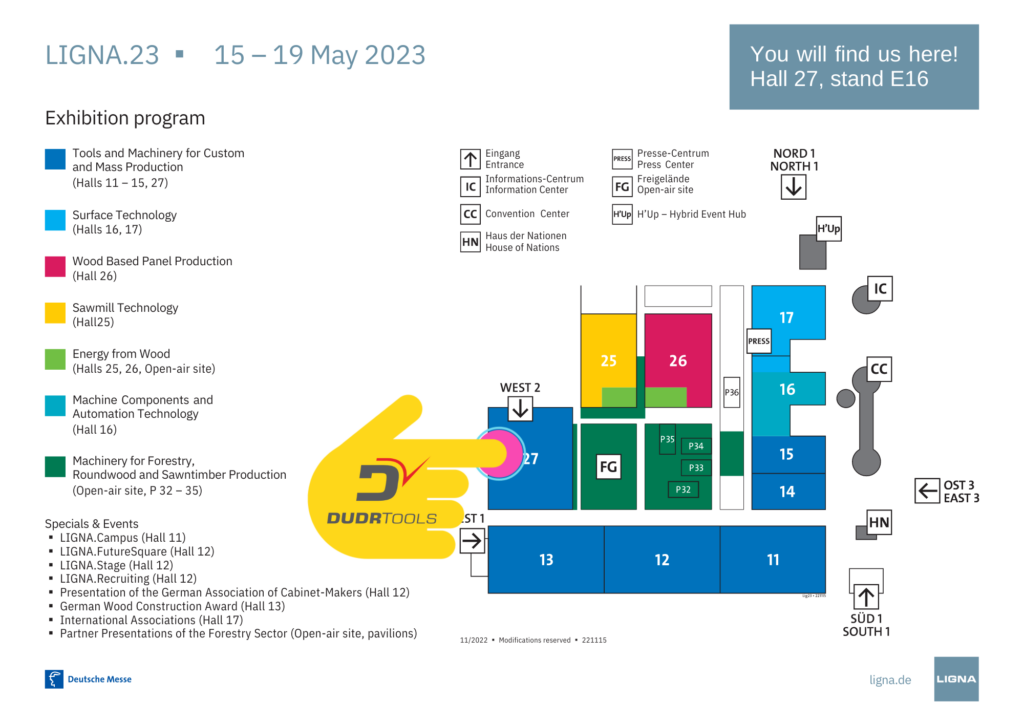

We will be the exhibitor at the Ligna trade fair

This world market place for innovations in the wood industry will take place from 15 to 19 May 2023. As one of the leading companies in the global woodworking market, we cannot afford to be absent. We look forward to seeing you there. You will find us in Hall 27, Stand E16, where we will be showcasing our high quality bandsaw blades and the comprehensive service and individual approach we offer to all our partners. We will also show you our advanced production of bandsaw blades, based on the development of our own production machines, towards the perfect tool for woodworking.

We walk together

We are always looking for opportunities to spend time together outside of work. One of the most popular activities for both adults and children is ice skating. During the winter we rent an ice rink several times and practice our skating skills. Someone starts with the first steps and slowly gets to know the ice. Someone takes a puck and a stick and challenges the more experienced skaters to a friendly game of hockey. But we all take away great experiences and go home with a smile on our face, pleasant tiredness in our legs and looking forward to the next time.

The Magnificent Nine Dudr Cargo Drivers

Our drivers are an important part of the Dudr Family. On their way to customers every day, they ensure the collection and delivery of bandsaw blades, so that the sawmills are always running at 100 %. They are in daily contact with Dudr´s production and logistics in Sazovice to ensure that the bandsaw blades are delivered to the customers without a hitch. They are a great group od people who like to get together and chat, for example over a pot of vegetable soap they have made together.

The year 2023 is here

The year 2022 is already behind us. During it, our Dudr collective grew with a lot of new faces, and even though we are all completely different, together we form a team that pulls together. So let’s go it a little further together next year in health and full strength. We appreciate your work and thank you all for being with us and making the Dudr Family together!

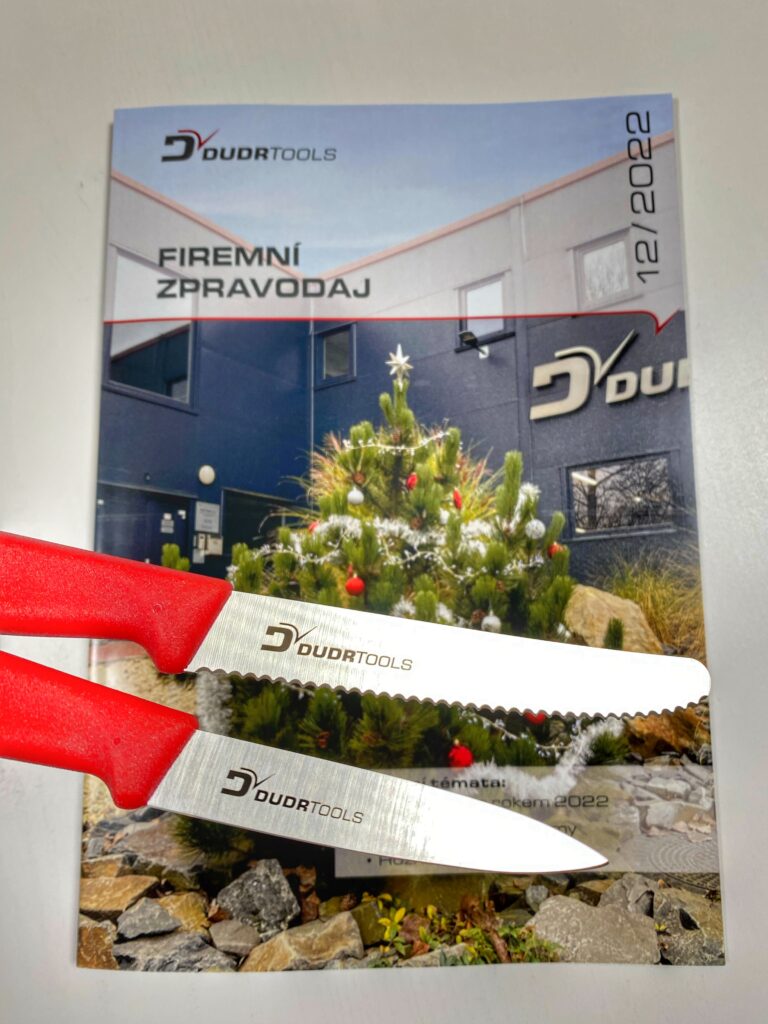

Christmas presents at Dudr Tools

At Dudr Tools, Ježíšek already rang the bell by the tree and brought beautiful Christmas presents for the whole team. In the pre-Christmas rush, we were able to refresh ourselves with the delicious Dudr Beer and cut some food with freshly unpacked Dudr knives. Before the start of the Christmas season, we would like to wish the entire Dudr Family all the best in their work.

In November we helped with exercise

In November we took part in special challenge, a sports and charity event organised by the Secondary School of Gastronomy from Zlín. For Dudr Tools employees and students, the challenge was to make 200,000 rope jumps together. If this goal was achieved, Dudr Tools would donate CZK 20,000 to the Handicap Zlín organisation. And how did it go?

Thanks to everyone who turned into kangaroos in their free time and honestly counted every jump, we succeeded. In total we made 268 710 jumps, of which the share of Dudr jumpers was a respectable 134 258 jumps!

We have shown that we can get excited and pull together. It also warms our hearts that we sweated not only to improve our physique, but also for a good cause, which brought the promised financial support to a charitable organization. On 1 December, Tomáš Dudr, together with representatives of the Zlín School of Gastronomy, handed over a check to the Handicap Zlín organisation.

Dudr Tools takes the first place

At the turn of September and October, we entered our company in the Year of New Technologies 2022 competition, which was announced by the Association of Small and Medium Enterprises and Entrepreneurs of the Czech Republic.

This was followed by two weeks of waiting to see how our project of an innovative optical method of measurement in the production of bandsaw blades could stand up to the competition of all the submitted projects. And it worked!

In mid-October, we received information that we were among the top three submitted projects and were invited to a ceremony announcing the winners and awarding the prizes, where the specific results would be revealed.

Our colleague Filip Dvorník represented us at the gala evening on Wednesday 26 October 2022 at the Ambassador Zlatá Husa hotel in Prague, and he was anxiously waiting to see if he would leave the stage with only a flower for second and third place or if he would have to give a speech of thanks for reaching the highest finish. And it worked again!

Dudr Tools scored! Filip spoke next to the experienced moderator Libor Bouček and tasted the feeling of 1st place on the stage and did not forget to mention that winning this award is due to the work of the entire Dudr Tools team.